A&M Manufacturing Co.Ltd

TEL: 01438 820822

MOB: 07789 882711 / 07905 354101

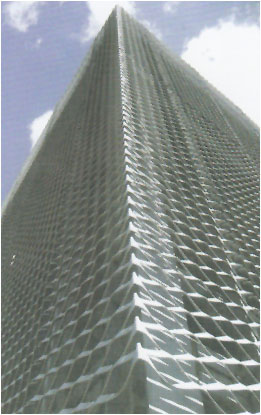

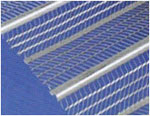

Expanded Metal

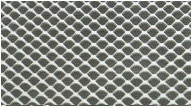

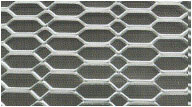

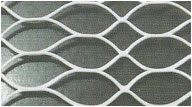

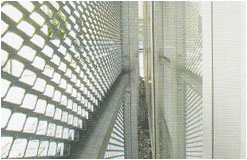

Expanded Metal is made from sheets of solid metal that are uniformly slit and stretched to create diamond shaped openings. As expanded metal is made, each row of diamond shaped is offset from the next. This product is called expanded metal. The sheet can be rolled to produce flattened expanded metal.

The lightweight properties and open area percentages of Expanded Metal allow it to be easily formed for a variety of energy saving applications, such as light diffusers, screens, grilles and filters. Expanded Metal is also manufactured in heavy guages for applications such as walkways, ramps and catwalks of all types.

Expanded Metal

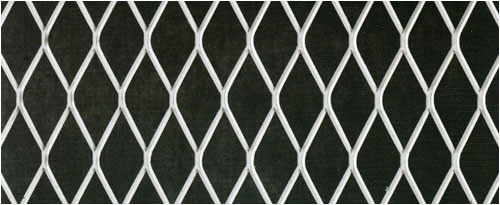

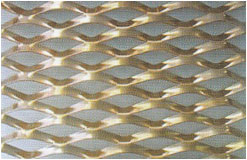

Standard Expanded Metal |

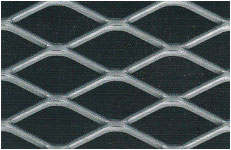

Flattened Expanded Metal |

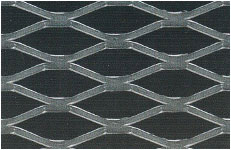

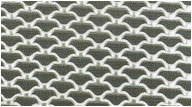

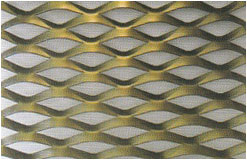

Decorated Expanded Metal

Major Material, Aluminum, Galvanised, Plain Steel, Stainless Steel, Minor Material, Cold Rolled, Hot Dipped, Hot Rolled.

|

|

|

|

|

|

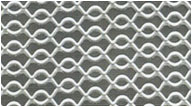

Anodizing Aluminum Expanded Sheet

Anodizing is the process of adding a layer of metal oxide to the surface of a metal. Aluminum is the most commonly anodized metal because it oxidizes very easily and anodization simply increases the thickness of this natural oxide layer. The primary advantages of anodizing aluminum are that the anodized layer has better adhesion and corrosion resistance than the base metal.

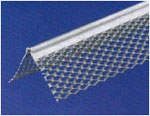

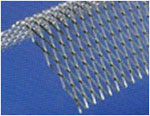

Angle Beads & Rib Lath

The intended use of Angle Beads is to help the formation of corners and abutments which are resistant to chips cracks and impact damage, protecting corners & edges and giving better shape.

|

|

|

|